Our Quality Management System

MARQUESS Electronics operates a comprehensive quality management system based on ISO 9001:2015 and IATF 16949:2016 standards. For automotive products, we follow IATF 16949:2016 requirements, while other products adhere to ISO 9001 standards when no specific customer requirements exist.

Incoming Quality Control

Material Receiving

All incoming materials are verified against specifications upon receipt.

Inspection & Testing

Comprehensive inspection and testing according to established standards.

Approval/Rejection

Materials are either approved for production or rejected and returned to suppliers.

Outgoing Quality Control

Final Inspection

Completed products undergo thorough final inspection before shipment.

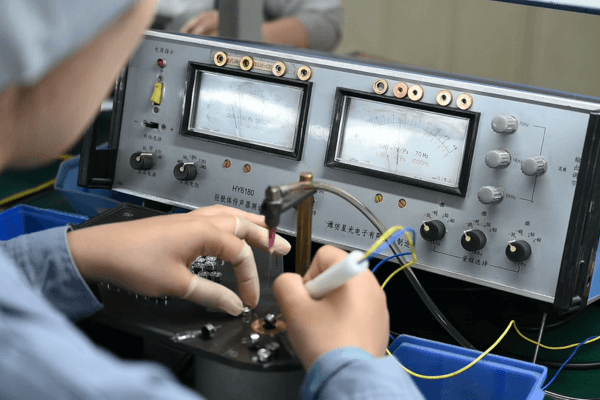

Performance Testing

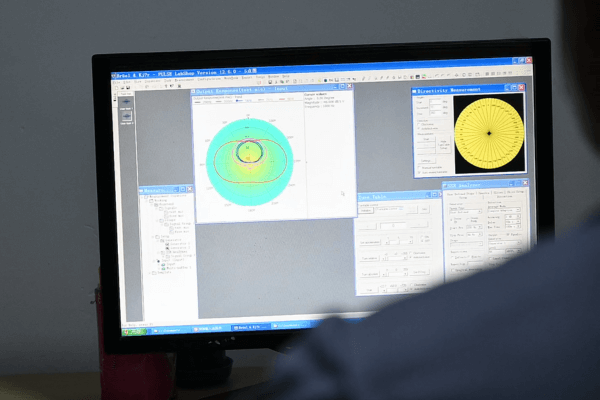

Acoustic performance verification using B&K analyzers in anechoic chambers.

Documentation & Shipping

Complete documentation accompanies each shipment with test reports.

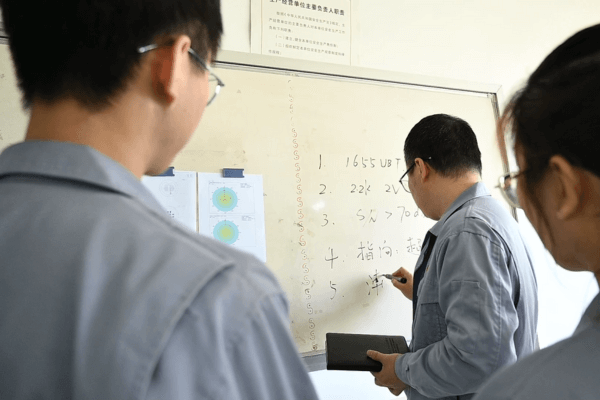

18 Quality Inspection Procedures

We implement 18 rigorous quality inspection procedures throughout our manufacturing process to ensure every product meets our high standards:

Raw Material Inspection

Comprehensive verification of all incoming materials

First Article Inspection

Initial sample verification before mass production

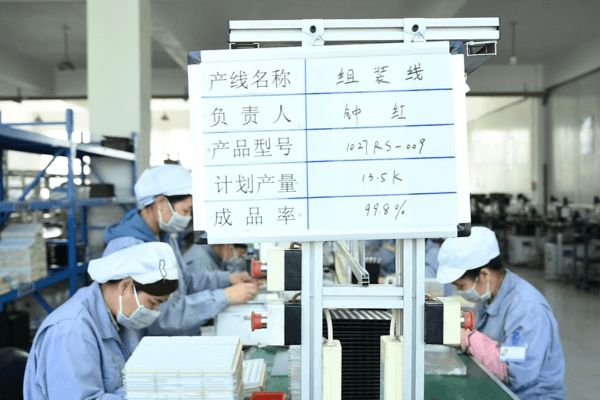

In-process Quality Control

Real-time monitoring during manufacturing

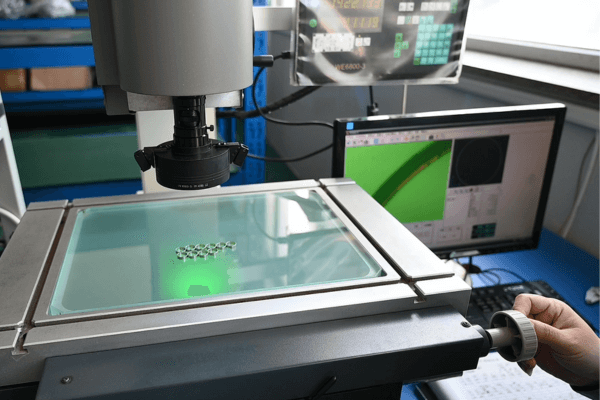

Dimensional Verification

Precise measurement of all critical dimensions

Acoustic Performance Testing

B&K analyzer testing in anechoic chambers

Environmental Testing

Temperature, humidity, and vibration testing

ESD Protection Testing

Electrostatic discharge protection verification

Life Cycle Testing

Durability and longevity testing

Reliability Testing

Long-term performance and stability testing