Our Manufacturing Facilities

MARQUESS operates from a 12,000 square meter facility equipped with advanced manufacturing equipment and cleanroom environments to ensure the highest product quality and consistency.

Advanced Manufacturing Facilities

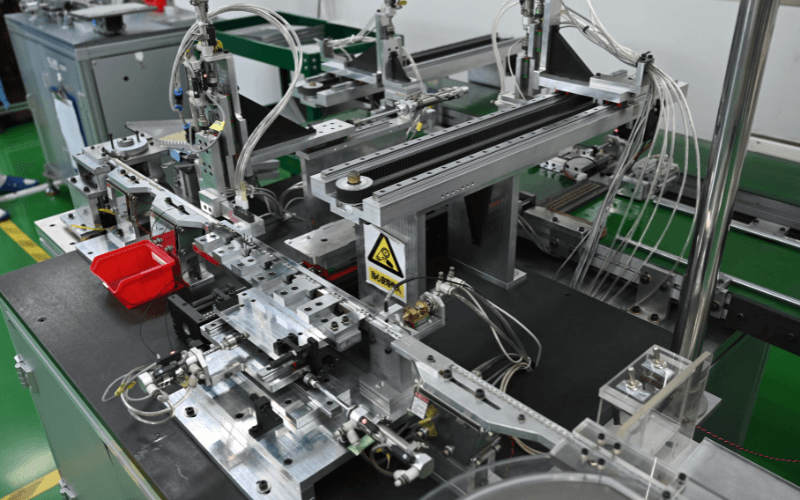

Our facility houses multiple automated production lines in Class 10,000 cleanrooms to ensure product quality and consistency.

- Automated Panasonic assembly lines

- Specialized polarization workshops

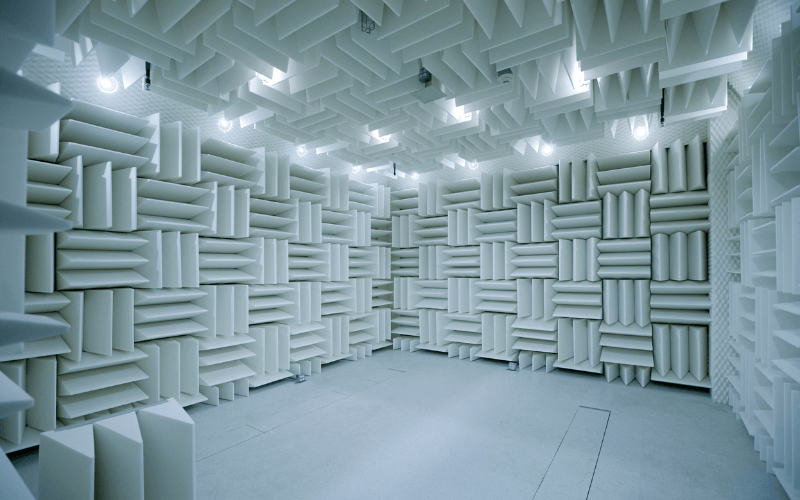

- CNAS standard acoustic laboratory

- Advanced injection molding capabilities

- SMT production lines for MEMS microphones

- 12 dedicated production lines

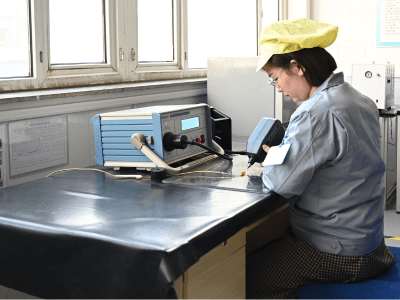

Comprehensive Quality Assurance

We employ 18 quality inspection procedures throughout our manufacturing process to ensure every product meets our high standards.

- B&K audio analyzers for precise acoustic measurements

- Environmental testing chambers

- Automated visual inspection systems

- ESD protection testing

- Life cycle and reliability testing

- Vibration and drop testing

Production Departments

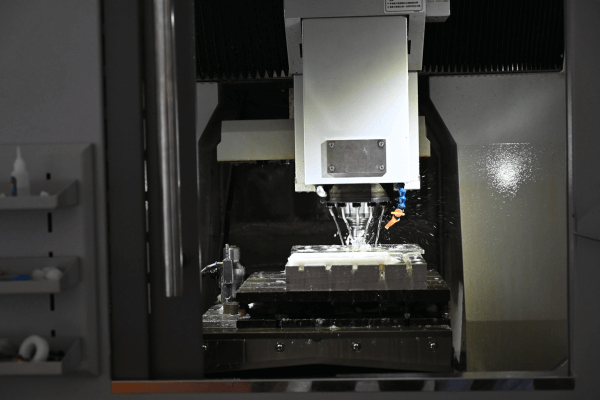

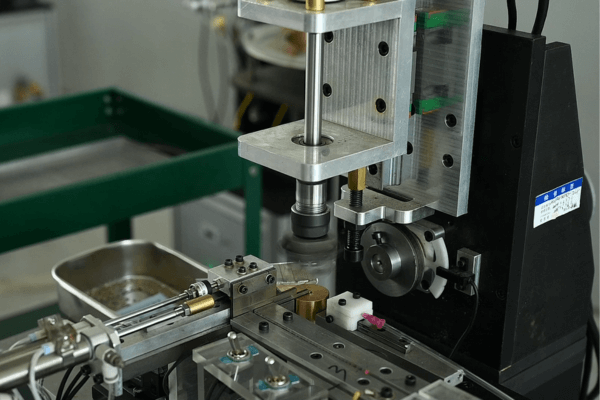

Mold & Prototyping

Precision CNC mold manufacturing and prototype development for microphone components and assemblies.

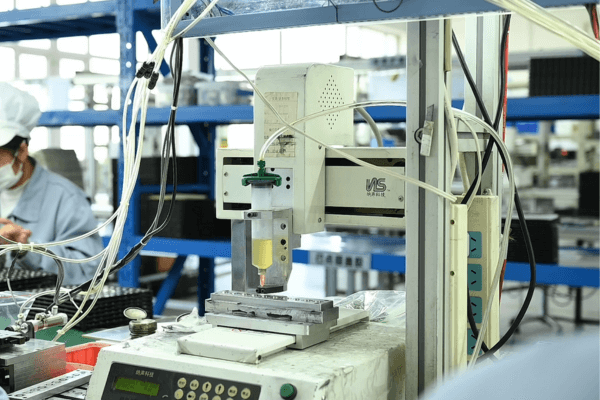

Precision Bonding

Automated adhesive dispensing for precise component assembly and structural integrity in microphone production.

Surface Finishing

Automated edge processing and surface treatment for microphone housing and component finishing.

Advanced Equipment

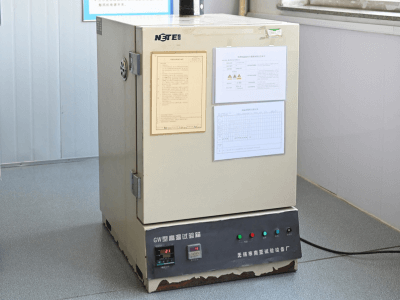

Damp Heat Testing

Temperature and humidity reliability testing

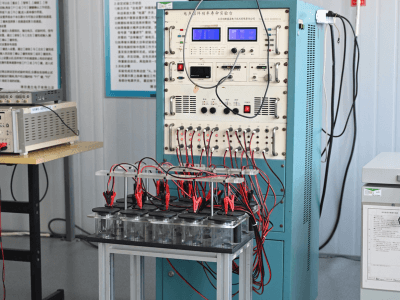

Aging Testing

Long-term performance and durability testing

ESD Testing

Electrostatic discharge protection verification

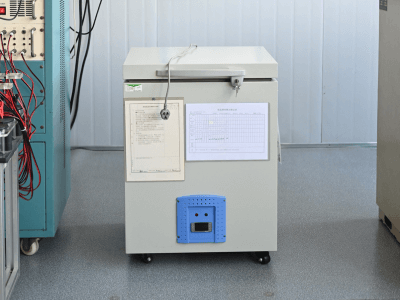

Ultra-low Temperature Testing

Extreme cold environment performance testing

High Temperature Testing

Elevated temperature operational reliability

Vibration Testing

Electromagnetic vibration endurance testing

Cleanroom Environment

Our Class 10,000 cleanrooms ensure minimal particulate contamination during the critical manufacturing processes:

- Temperature and humidity controlled environment

- HEPA filtration systems

- ESD protective flooring and equipment

- Strict personnel gowning procedures

- Regular air quality monitoring

- Positive pressure maintenance

Class 10,000

Cleanroom Standard

≤10,000 particles per cubic foot